Payment Type:T/T,Paypal,Others

Incoterm:FOB,CIF,EXW,FCA,Express Delivery

Transportation:Ocean,Land,Air,Express

Port:Shanghai,Shenzhen,Ningbo

$3500-49999Piece/Pieces

$2.5≥50000Piece/Pieces

Brand: YXGM

Place Of Origin: China

Species: Ceramic Parts

Application: Industrial Ceramic

Material: Alumina Ceramic

Processing Service: Cutting, Punching, Moulding

Material: 95~99% Al2O3

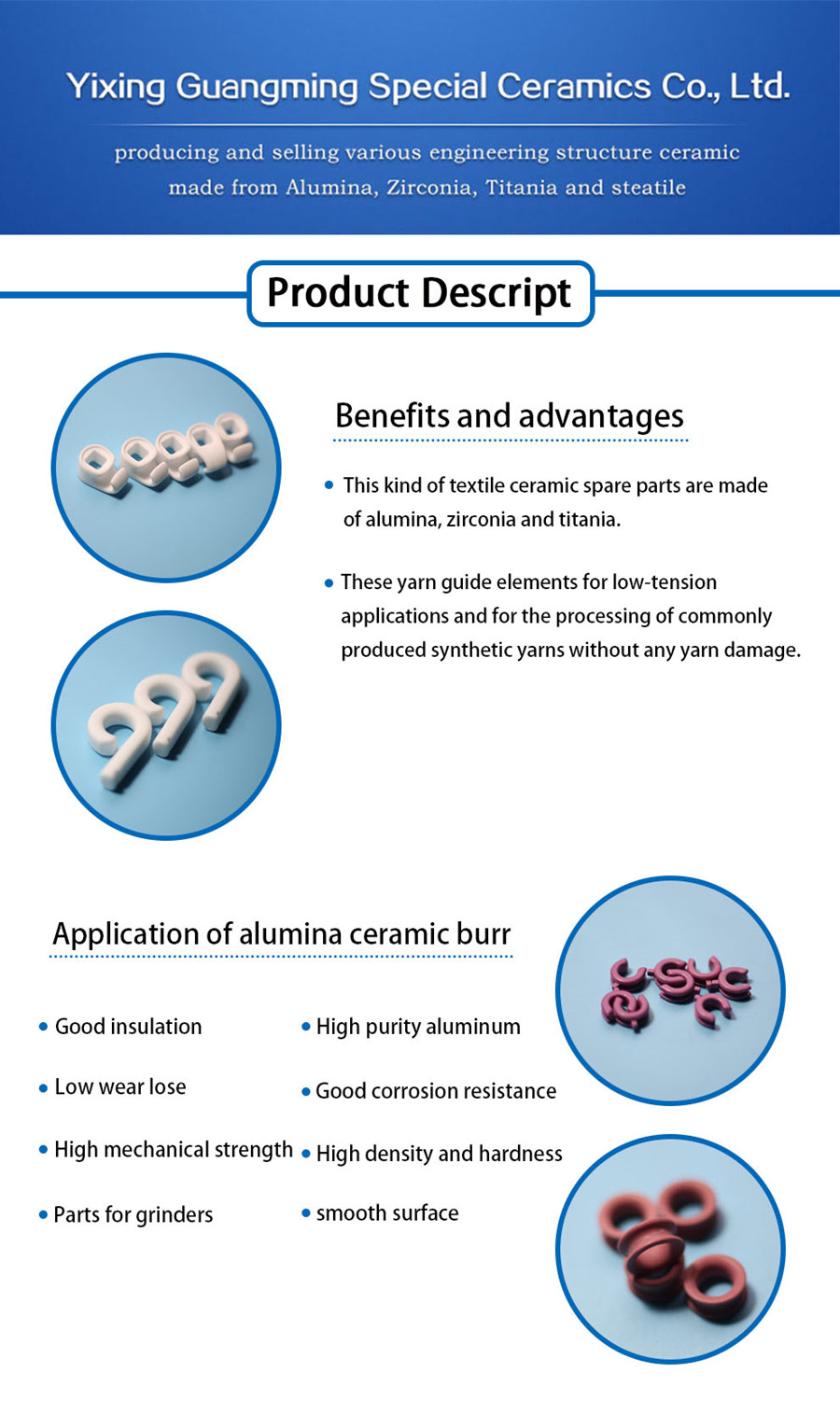

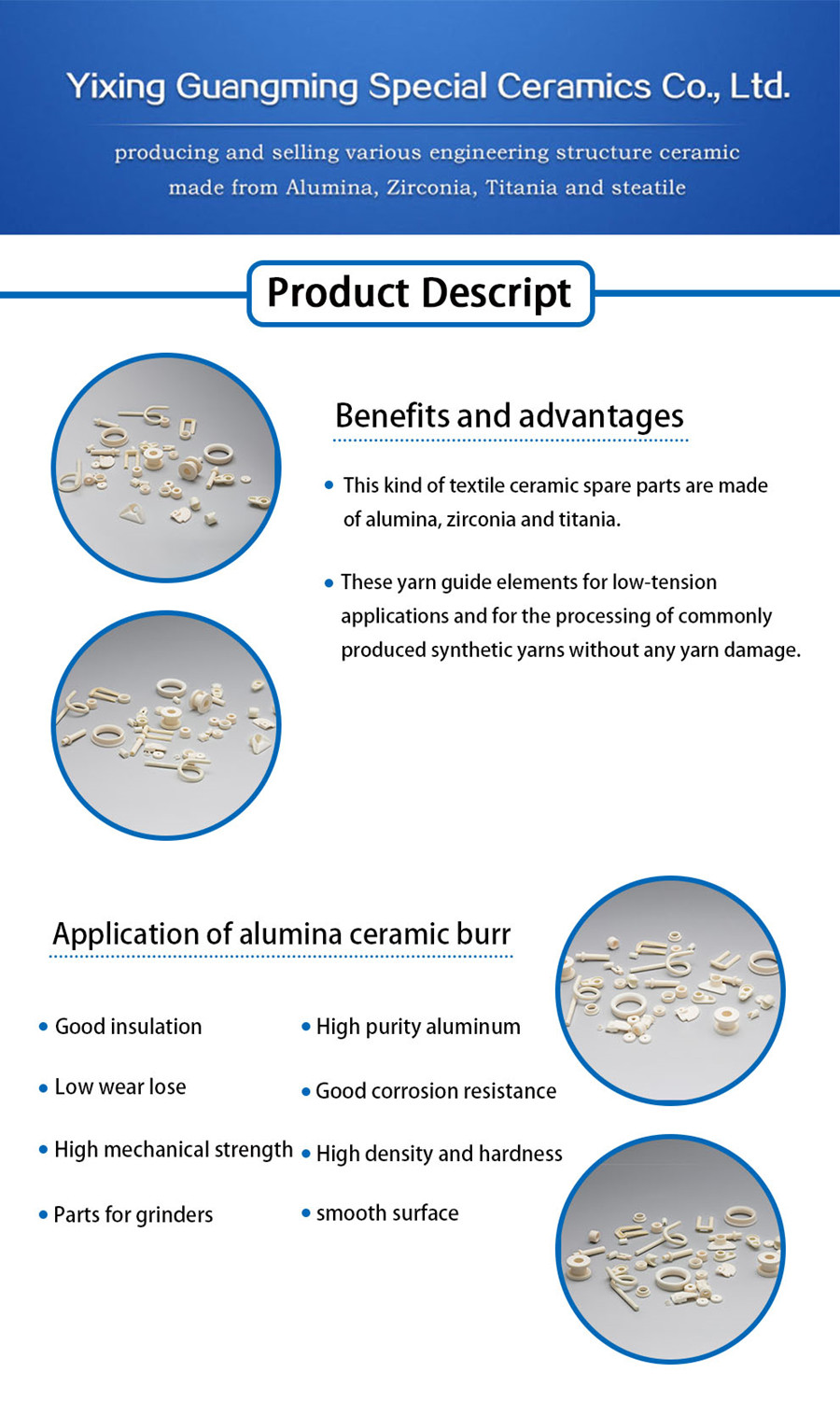

Color: White,Ivory,Pink

Application: Textile guides

Density: 3.7-3.9g/cm3

Certification: ISO9001:2015,ROHS

Packaging: Pallet

Productivity: 200000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: CHN

Supply Ability: 200000pcs/month

Certificate: ISO9001:2015,ROHS

HS Code: 8547100000

Port: Shanghai,Shenzhen,Ningbo

Payment Type: T/T,Paypal,Others

Incoterm: FOB,CIF,EXW,FCA,Express Delivery

Custom Alumina Textile Ceramic Guide

Alumina Textile Ceramics are a type of ceramic material that is commonly used in various industrial applications. They are known for their high strength, excellent thermal stability, and resistance to wear and corrosion. In this guide, we will discuss the properties, applications, and manufacturing process of alumina textile ceramics.

Properties of Alumina Textile Ceramics:

- High strength: Alumina textile ceramics have a high tensile strength, making them suitable for applications that require durability and resistance to mechanical stress.

- Thermal stability: These Al2O3 Ceramics can withstand high temperatures without undergoing significant deformation or degradation.

- Wear resistance: Alumina textile ceramics have excellent wear resistance, making them suitable for applications that involve friction and abrasion.

- Chemical resistance: They are resistant to a wide range of chemicals, making them suitable for use in corrosive environments.

- Electrical insulation: Alumina textile ceramics have high electrical resistance, making them suitable for applications that require electrical insulation.

Applications of Alumina Textile Ceramics:

- Furnace linings: Alumina textile ceramics are commonly used as furnace linings in industries such as steel, glass, and ceramics. They can withstand high temperatures and thermal shock, making them ideal for this application.

- Heat shields: These ceramics are used as heat shields in various applications, including aerospace, automotive, and electronics. They provide thermal insulation and protect sensitive components from high temperatures.

- Filtration: Alumina textile ceramics are used in filtration applications, such as hot gas filtration and molten metal filtration. They have excellent porosity and can effectively remove impurities from gases and liquids.

- Wear components: Alumina textile ceramics are used to manufacture wear components such as bearings, seals, and nozzles. They provide high wear resistance and can withstand harsh operating conditions.

-Ceramic Insulator: These ceramics are used as insulators in electrical and electronic applications. They provide electrical insulation and thermal stability, making them suitable for use in high-voltage applications.

Manufacturing Process of Alumina Textile Ceramics:

1. Raw material preparation: The first step in manufacturing alumina textile ceramics is the preparation of raw materials. Alumina powder is typically used as the main ingredient, along with other additives to enhance the properties of the final product.

2. Mixing: The raw materials are mixed together to ensure a homogeneous distribution of particles and additives.

3. Shaping: The mixture is then shaped into the desired form using various techniques such as extrusion, injection molding, or tape casting.

4. Drying: The shaped parts are dried to remove any moisture and prepare them for the next step.

5. Firing: The dried parts are fired at high temperatures to sinter the particles together and form a dense ceramic structure. The firing process also helps in achieving the desired properties of the final product.

6. Finishing: After firing, the alumina textile ceramics may undergo additional processes such as machining, grinding, or polishing to achieve the desired dimensions and surface finish.

In conclusion, alumina textile ceramics are versatile materials that offer a wide range of properties and applications. Their high strength, thermal stability, and resistance to wear and corrosion make them suitable for various industrial applications. The manufacturing process involves raw material preparation, mixing, shaping, drying, firing, and finishing.

Technical Parameters:

Item Unit Al2O3 95%-97% Al2O3 99% Desity g/cm3 3.7 3.85 Flexural Strength Mpa 300 340 Compressive Strength Mpa 3400 3600 Modulus of Elaslicity Gpa 350 380 Impact Resistance Mpa m1/2 4.0 5 Weibull Moudulus m 10.0 10 Vickers Hardness HV0.5 1200.0 1300 Thermal Expansion Coefficent 10-6K-1 5.0-8.3 5.4-8.3 Thermal Conductivity W/mK 24 27 Thermal Shork Resistance △T℃ 250 270 Maximum Use Temperature ℃ 1600 1650 Volume Resistivity at 20℃ Ω ≥1014 ≥1014 Dielectric Constant KV/mm 20 25 Open Porosity % 0 0 Dielectric Constant ξr 10 10 Dielectric Loss Angle Tanσ 0.001 0.001